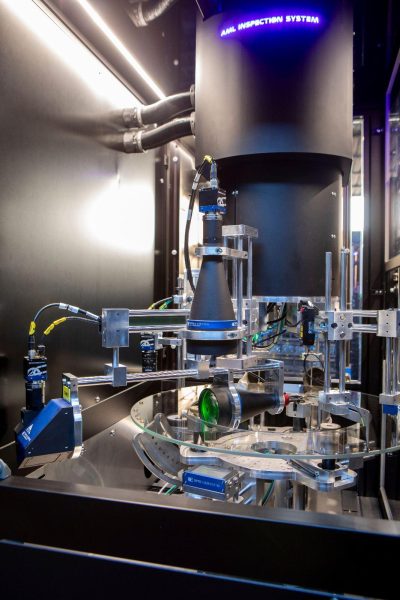

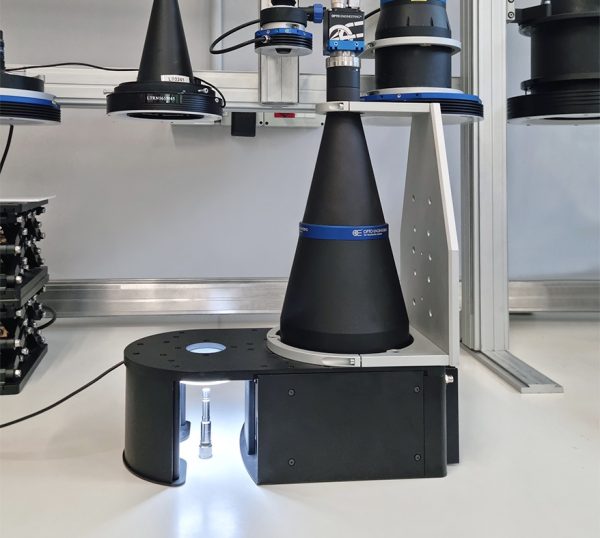

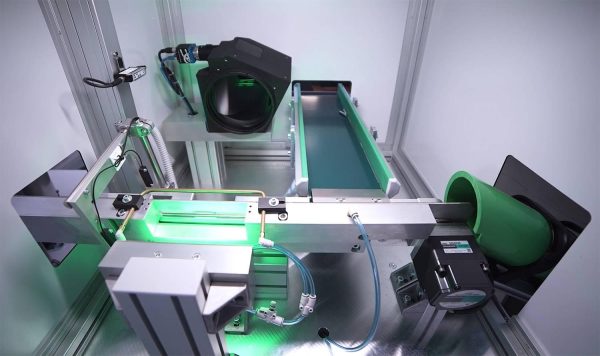

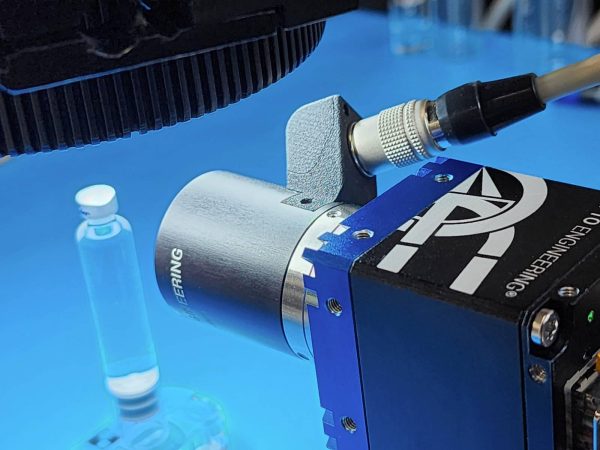

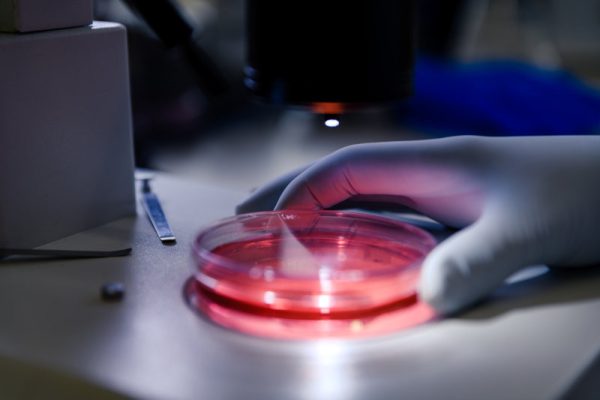

ITALA® cameras: Robots eyes in remote inspection systems

AUT integrates Opto Engineering® ITALA® cameras and optics on its robots for Non-Destructive Testing (NDT) and Evaluation of critical infrastructures in the Oil and Gas, Aerospace and Nuclear industries.